Britlift launches new modular roof truss lifter

Lifting beam manufacturer Britlift is launching an innovative new modular lifting beam specifically designed for lifting roof trusses.

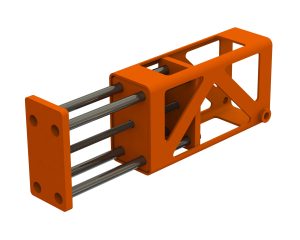

The Britlift Roof Lifting Beam (RLB) is a lightweight steel beam. Its unique modularity, which is patent pending, enables each component to be easily handled and assembled by the site team. It also makes the beam simple to adjust as well as easy to store, transport, maintain and inspect.

Trussed rafters (roof trusses) provide a structural framework to support the roof fabric, ceilings or floors of buildings in both residential and commercial structures. Britlift has designed the beam to improve safe lifting of these trusses. It also significantly reduces waste on construction sites and for off-site housing manufacturers.

huge savings on timber for construction companies and prefab home manufacturers

The modular RLB (End/Connection Piece)

Liam Botting, managing director of Britlift, said: “Typically on British construction sites, roof trusses are crane lifted by attaching spare structural timbers to the frame. Once the lift is complete, these timbers are stuck in situ for the life of the roof. They are not required to support the structure, so they are essentially waste wood. Our steel beam RFL is designed to be reused for years, potentially leading to huge savings on timber for construction companies and prefab home manufacturers.”

Proof load tested to 2x WLL, the RFL’s lightweight design means it can be safely handled by two people, meaning it is below the manual handling threshold. It comes with a detailed set of user and assembly instructions, along with an EC Declaration of Conformity. It is also UKCA and CE marked.

As a modular system the beam can be increased and decreased in span, to suit any size of roof truss.

Our steel beam RFL is designed to be reused for years

The modular RLB within custom stillage

comes with a detailed set of user and assembly instructions, along with an EC Declaration of Conformity. It is also UKCA and CE marked.

“Housebuilding is continuously looking for efficiencies to cut carbon emissions, reduce waste and make financial savings,” added Liam. “Single use timbers for lifting roof trusses are non-value-added materials. Replacing them with a certified product specifically designed for the task is a tick in all three of these boxes for both construction contractors and off-site manufacturers.”

RLB assembled and in place ready to lift

the RFL’s lightweight design means it can be safely handled by two people, meaning it is below the manual handling threshold

The RFL is available now to order from Britlift’s UK manufacturing facility. For further details, visit the product page:

https://britlift.com/roofliftingbeam/

For more information please contact Britlift

Based in Dorset, UK, Britlift works with a global client base, providing an end-to-end lifting equipment engineering design service including calculations, design, manufacture, certification, and rig design. The qualified mechanical and structural engineers at Britlift will work with the client during the design phase, ensuring the most efficient, effective, safe and suitable solution is engineered, be that a lifting beam or frame, a bespoke handling or lifting tool, complex rig design, or FEA. Its Traditional Modular spreader beams and Multilifter (ML180) are also available in a variety of standard sizes.