Roof Truss Lifting Beam from Britlift

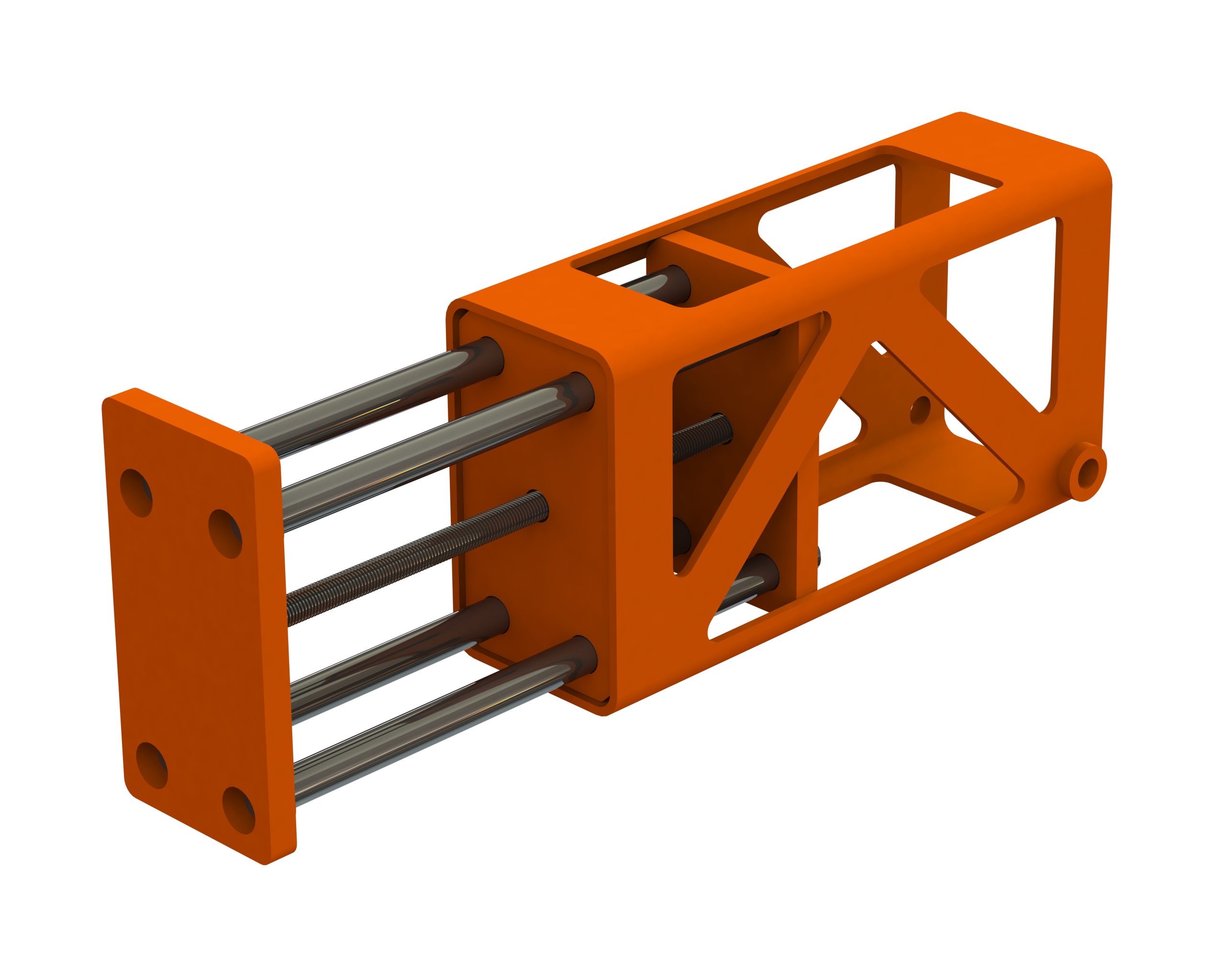

The PATENTED Britlift Roof Lifting Beam (RLB) is a lightweight steel, modular lifting beam which has been specifically designed to lift (timber) trussed rafters (aka roof trusses).

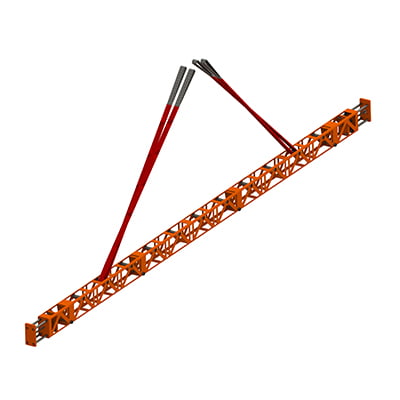

Roof Truss Lifting Beam – 10m

Proof load tested to 2x WLL, this patent pending product comes with a detailed set of User/Assembly Instructions, EC Declaration of Conformity, and is UKCA and CE marked.

Roof Truss Lifting Beam – 7m

Given that the system is modular, the beam can be increased and decreased in span, to suit any size of roof truss.

Short Beam with Full Sling and Roof

The patented connection system allows for ease and speed of assembly, handling, use and storage.

Slotting within the structure of a timber roof trusses, the main purpose of the RFL is to reduce timber wastage by replacing the traditional roof truss lifting method (structural timber in the roof structure installed for the sole purpose of lifting the roof structure, which become immediately redundant once the lifting is completed), with a lightweight steel beam that is reusable.

Reducing the non-value added materials within the build system with a fully tried, tested and certified product was the key driver for it development.

By reducing the non-value added activities and materials within the overall build system, there is an increase in Pre-Manufactured Value which in-turn is a key driver for access to the likes of Homes England funded projects.

The PATENTED modular lightweight design allows each component to be easily handled, and assembled by the site team, easy to store and transport, easy to maintain and inspect, and simple to adjust.

Trussed rafters (roof trusses) provide a structural framework to support the roof fabric, ceilings or floors of buildings in both residential and commercial structures.

“Typically on British construction sites, roof trusses are crane lifted by attaching spare structural timbers to the frame. Once the lift is complete, these timbers are stuck in situ for the life of the roof. They are not required to support the structure, so they are essentially waste wood. Our steel beam RLB is designed to be reused for years, potentially leading to huge savings on timber for construction companies and prefab home manufacturers.”

“House-building is continuously looking for efficiencies to cut carbon emissions, reduce waste and make financial savings,” Botting added. “Single use timbers for lifting roof trusses are non-value-added materials. Replacing them with a certified product specifically designed for the task is a tick in all three of these boxes for both construction contractors and off-site manufacturers.”

Looking for something different?

Britlift can design and manufacture any below-the-hook lifting system to suit any application and environment.

If you have a 2 point lift and no height restrictions then maybe its a spreader beam you need? Visit the products page (above) and click on spreader beams.

Enquiries

Please fill out the below contact form and include any additional comments you feel are important for us to know.

Please include the weight being lifted, length required, type of top and bottom lifting points (distances if applicable) and any special standards or specifications.

"*" indicates required fields