Description

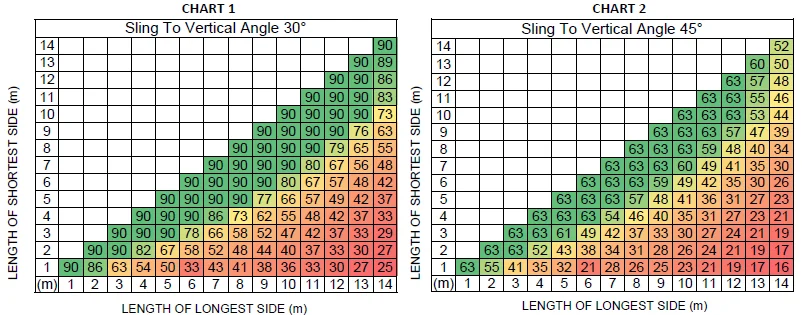

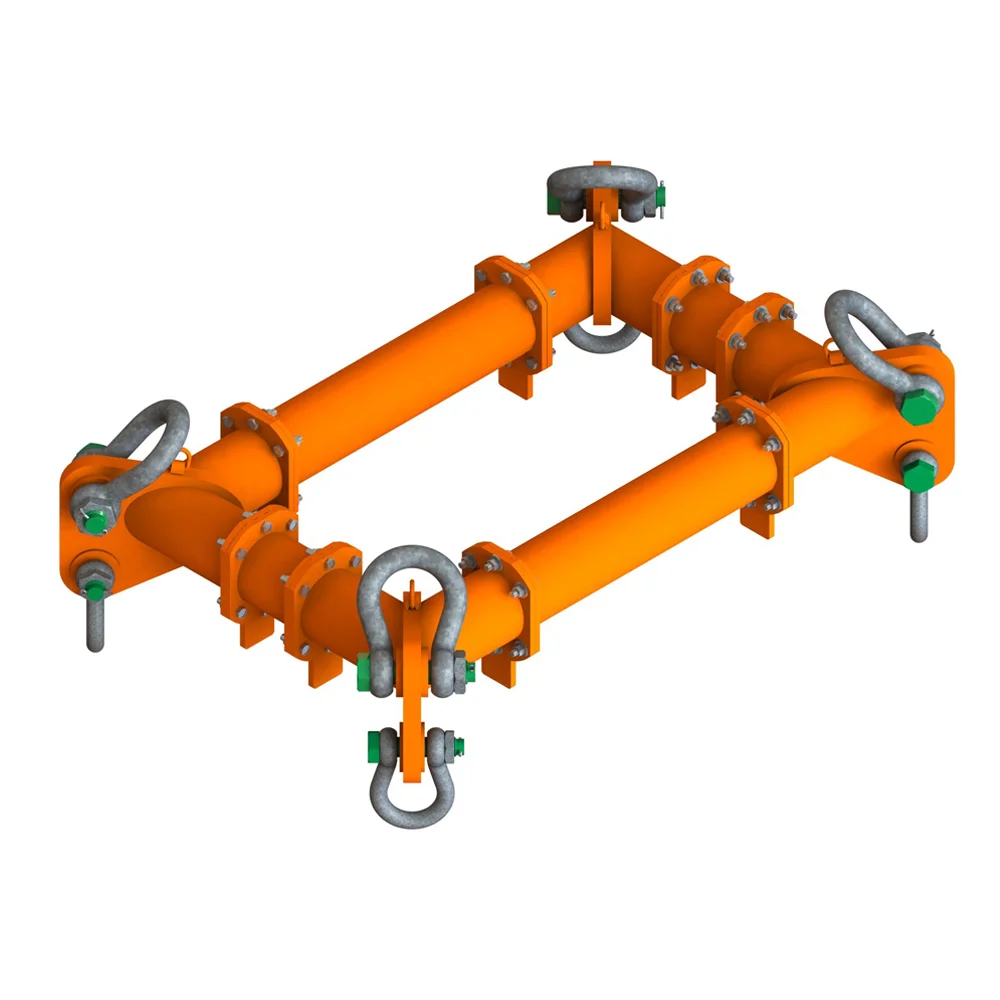

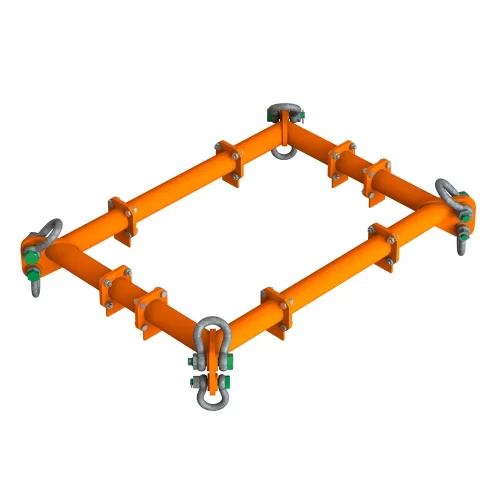

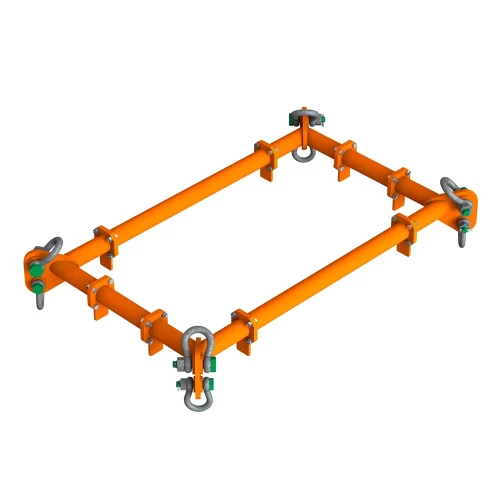

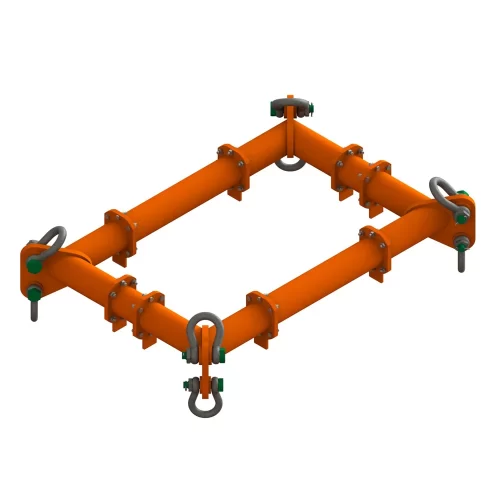

The Britlift Traditional Modular Spreader Frame is our first choice when adjustability, flexibility, speed of supply and/or self-weight is critical. This frame is rated for a maximum vertical load of 90 tonnes and a maximum span of 14 meters by 14 meters. This system is modular in construction and may be reassembled by trained riggers using different strut combinations to achieve the spans displayed in charts 1 and 2.

The Britlift Traditional Modular Spreader Frame is our first choice when adjustability, flexibility, speed of supply and/or self-weight is critical. This frame is rated for a maximum vertical load of 90 tonnes and a maximum span of 14 meters by 14 meters. This system is modular in construction and may be reassembled by trained riggers using different strut combinations to achieve the spans displayed in charts 1 and 2.

The sling angle used selected during the rigging of this item is crucial to the safe use of the frame. This angle will affect the weight of the load that can be safely lifted.

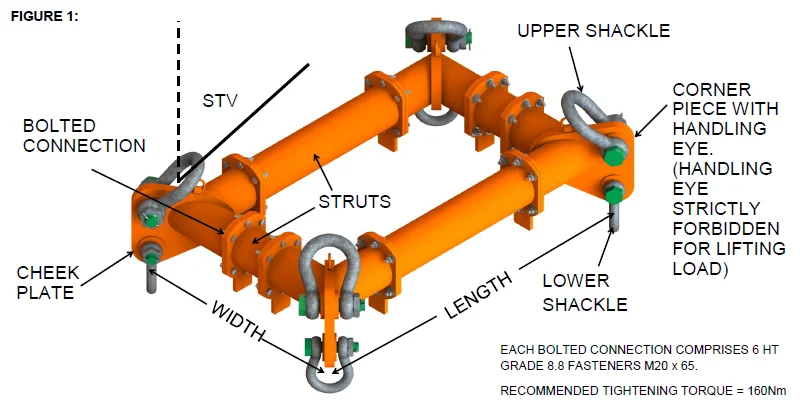

Each bolted connection comprises 6 ht grade 8.8 fasteners m20 x 65.

Recommended tightening torque = 160nm

• STV (sling to vertical) angle must be no more than 45°.

• The WLL (working load limit) of a single corner piece is 22.5 tonnes (90 tonnes combined). Do not exceed this weight at one corner of the frame.

• Check that no rigging equipment clashes with the struts. The frame must only be loaded through the shackle pin holes at each corner.

The charts below (chart 1 and chart 2) show all acceptable configurations for this modular spreader frame when the sling to vertical angle is 30 degrees (chart 1) and 45 degrees (chart 2). To read the charts, start on the longest side and go up to the shortest side. The numbers in the table represent the working load limit (t) for each of the configurations.